Stainless steel welded U tubes are essential components in many industries, thanks to their unique shape and material properties. Understanding what they are, the types available, and where they are used can help you see their importance in everyday applications. Let’s dive in!

What Are Stainless Steel Welded U Tubes?

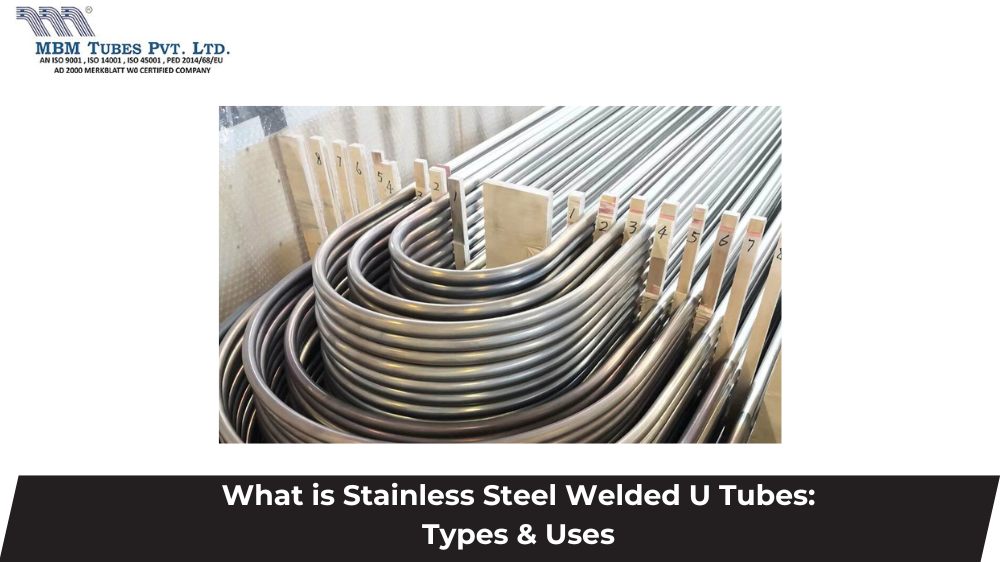

Stainless steel welded U tubes are tubes shaped like the letter “U” that are made from stainless steel. These tubes are created by welding two straight tubes together at the ends, forming a U shape. The welding process makes them strong and leak-proof. The Stainless steel welded U tube material is chosen for its excellent resistance to rust and corrosion, making these tubes perfect for various environments.

Types of Stainless Steel Welded U Tubes

There are several types of stainless steel welded U tubes based on their material composition and dimensions:

- Type 304 is the most common stainless steel grade, known for its good corrosion resistance and formability. It is widely used in various applications, including food and beverage processing.

- Type 316 offers better corrosion resistance, especially against chlorides and seawater. It is often used in marine applications and chemical processing.

- Duplex Stainless Steel combines the properties of austenitic and ferritic stainless steels. It is stronger and more resistant to stress corrosion cracking, making it suitable for high-pressure applications.

- Custom Sizes and Shapes Manufacturers can also create U tubes in various sizes and thicknesses to meet specific project requirements, ensuring that they fit perfectly into existing systems.

Where Are They Used?

Stainless steel welded U tubes are used in many industries. Here are some common applications:

1. Heat Exchangers

These tubes are commonly found in heat exchangers, where they help transfer heat between fluids. The U shape allows for efficient heat transfer, making them ideal for heating and cooling in places like power plants and HVAC systems.

2. Boilers

These tubes carry water and steam in boiler systems. They are designed to withstand high temperatures and pressures, ensuring the boiler operates safely and efficiently.

3. Oil and Gas

In the oil and gas industry, pipelines and processing plants use stainless steel welded U tubes. Their ability to resist corrosion and handle extreme conditions makes them suitable for transporting various fluids, including crude oil and natural gas.

4. Food and Beverage

In food processing, these tubes are crucial for transporting liquids without contamination. The non-reactive nature of stainless steel ensures that food safety standards are maintained.

5. Pharmaceuticals

The pharmaceutical industry requires strict hygiene. Stainless steel welded U tubes are often used in the production of medicines and vaccines, where sterility is a must.

6. Water Treatment

These tubes are also used in water treatment facilities, helping transport and process water effectively. Their corrosion resistance ensures they remain functional in harsh chemicals.

7. Marine Applications

In marine environments, equipment faces challenges from saltwater. Stainless steel welded U tubes are suitable for marine applications, such as heat exchangers on ships, because they resist corrosion.

Why Choose Stainless Steel Welded U Tubes?

Choosing stainless steel welded U tubes offers several benefits:

- Longevity: Their resistance to rust means they last longer than other materials.

- Efficiency: Their design allows for effective heat transfer and fluid movement.

- Versatility: They can be adapted for various applications across different industries.

- Safety: The strength and reliability of these tubes ensure safe operations, especially in critical systems.

Conclusion

Stainless steel welded U tubes are crucial in many industries, providing strength, durability, and versatility. Their unique U shape, various types, and corrosion-resistant properties make them perfect for applications in heat exchangers, boilers, oil and gas, food processing, pharmaceuticals, water treatment, and marine settings.